VAV compact controller for laboratory and pharmaceutical applications

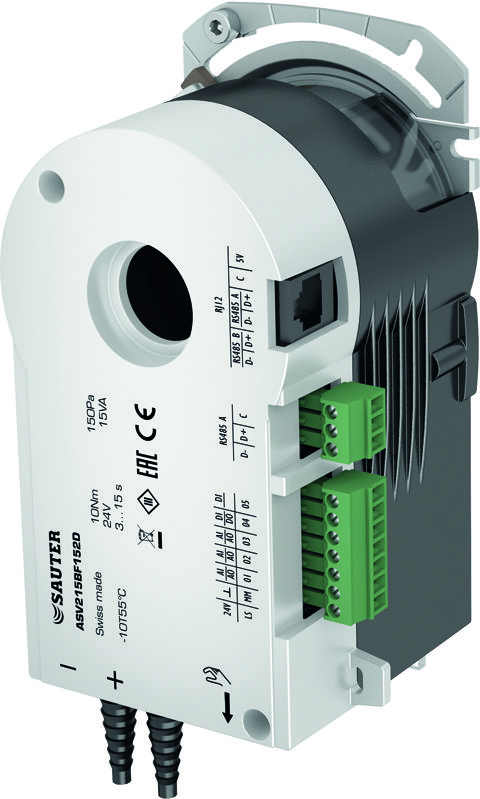

ASV215BF152*

How energy efficiency is improved

Allows demand-based volume flow control in order to optimise energy consumption in ventilation systems. Differential pressures of at least 1 Pa can be controlled to allow minimal volume flows at the lowest duct pressure and energy consumption.

Caracteristicas

-

Controlling the return air in fume cupboards and controlling the supply and return air in laboratories, clean rooms, hospital wards and operating theatres using a VAV box or a damper and flow probe

-

Static measurement of differential pressure based on the capacitive method of measurement

-

Zero point can be calibrated using software

-

Adjustable end values of the differential pressure measuring range

-

50…150 Pa

-

100…300 Pa

-

-

Can be used for measuring in areas with dirty or contaminated return air

-

Brushless DC motor guarantees minimum energy consumption and a long service life

-

Electromechanical torque-based switch-off for safe operation

-

Extremely simple installation due to self-centring shaft adapter

-

Disengageable gear unit for manual adjustment and positioning of damper

-

Easy programming of the following applications using the SAUTER CASE VAV software:

-

Volume flow control

-

Room pressure control

-

Duct pressure control

-

Flow control for fume cupboards

-

-

Efficient control algorithm for fast control loops

-

Integrated second control loop for:

-

Room-pressure control: can be ideally combined with EGP 100 with symmetrical measuring range

-

Fume-cupboard control ideally combined with SVU 100, SGU 100 and FCCP 200

-

-

2 x RS-485 bus interface on RJ12 and connection terminal

-

Up to 31 subscribers in a segment with SLC (SAUTER Local Communication) protocol

-

Communication within network via BACnet MS/TP

-

Integration of EY-RU 3** digital room operating units

-

FCCP 200 display and alarm unit for fume-cupboard control or room monitoring

-

-

Input and output signals for connecting:

-

Setpoints and actual values

-

Analogue output

-

Priority control via switching contacts

-